Day 1 :

Biography:

Abstract:

Keynote Forum

Geoffrey R Mitchell

Tbilisi State Medical University, Georgia

Keynote: Rsin based composites, the ultimate green material

Time : 10:30-11:00

Biography:

Geoffrey Mitchell is passionate about direct digital manufacturing which enables products to be manufactured directly from a digital design without the need for specialist tooling or moulds and the development of novel materials to support the emerging technologies associated with DDM. He brings a wealth of experience working with polymer based materials both natural and synthetic. He is fascinated by the links between the scales of structures present in all materials and especially biopolymers. He is focused on using processing as a tool to control those scales of structure and hence define the final products of the material.Abstract:

The current world-wide focus on Climate Change has led to a re-evaluation of all aspects of manufacturing in order to reduce the level of carbon dioxide released in to the atmosphere. One approach has been to look to the natural world for the raw material supply on the basis that this is sustainable. This has led to an over simplification of the problem. We still need to minimize the consumption of energy and the inclusion of other non-sustainable sources of raw materials as well as minimizing waste production. As part of the Research Programme of the Centre for rapid and Sustainable Product Development we have initiated a major stand of work under the umbrella of “Adding value to Forest based Products”: The basic objective is to increase the economic value of forests to ensure their stability and to underpin biodiversity, both objectives are critical to the Paris Accord (United Nations Framework Convention on Climate Change dealing with greenhouse gases emissions mitigation, adaptation and finance). Historically, Portugal was the leading exporter in the world of Rosin, a material obtained from pine resin. The pine forests of Portugal are particularly suited to the production of rosin, but in recent years the forests have declined due to poor maintenance and cheap importants of rosin from other countries. Pine resin as tapped from trees contains a mixture of Rosin which itself is a mixture of chemical compounds, water and turpetine. The Rosin is extracted using a particularly eco-friendly process require no other input than the pine resin. The output streams are Rosin, Turpentine and clean water. In order to maintain the green creditionals we are look to products which require no further processing of Rosin both to reduce waste and also minimize energy consumption. To date we have produced an eco-foam, composites and scaffolds for tissue engineering.

Keynote Forum

Blanka Rihova

Director Institute of Microbiology AS CR, Czech Republic

Keynote: HPMA Copolymer-Bound Doxorubicin as Endogenous Vaccine Substantially Increases Therapeutic Effect of Check-Point Blockade Monoclonals: Acute versus Chronic Model

Time : 11:00-11:30

Biography:

Blanka Rihova is Professor of Immunology, Charles University, Prague, the Czech Republic and Adjunct Professor of Pharmaceutics and Pharmaceutical Chemistry, University of Utah, Salt Lake City, USA. In 2000–2007 she was a director of the Institute of Microbiology, Academy of Sciences of the Czech Republic. She is president of Czech Immunology Society, vice-president of Czech Learned Society and vice-president of Scientific Council of CAS.

Abstract:

DOXHYD-HPMA is doxorubicin bound through hydrazone bond to synthetic polymeric carrier based on N-(2-hydroxypropyl)methacrylamide. It is effective anticancer polymeric prodrug with decreased side-toxicity and the ability to induce immunogenic cancer cell death releasing site-specific tumor antigen and thus acting as endogenous vaccine. We have compared chemo-immunotherapy combination treatment of EL4 T cell lymphoma and 4T1 breast carcinoma with DOXHYD-HPMA and with immune checkpoint blocking anti-CTLA-4 and anti-PD-1 MAbs either alone or in a mixture. To document the role of intestinal microbiota we use germ-free (GF) mice and GF mice monocolonized with Bifidobacterium thetaiotamicron. Acute model of disease when mice are transplanted once with a lethal dose of tumor cells was compared with chronic model where mice are injected six times every other day with a low number of tumor cells. Healthy mice treated with anti-CTLA-4 and anti-PD-1 mAbs did not show any signs of toxicity while significant co-toxicity was seen in cancer-bearing mice. Treatment with checkpoint inhibitors only exerted a very limited cancer response as no long term survivors (LTS) were recorded. On the other hand more than 60% of mice injected also with therapeutically suboptimal dose of DOXHYD-HPMA survived disease-free for more than 100 days. Those suffering from chronic model of cancer showed considerably higher proportion of PD-1+ cells in tumor microenvironment and reacted substantially better to anti-CTLA-4 or anti-PD-1 treatment than mice with the acute model

Geoffrey R Mitchell photo" title="Geoffrey R Mitchell" class="img-responsive thumbnail pull-left">

Geoffrey R Mitchell photo" title="Geoffrey R Mitchell" class="img-responsive thumbnail pull-left">

Biography:

Abstract:

- Biopolymer Applications | Advanced Biopolymers | Biopolymers For Tissue Engineering And Regenerative Medicine

Session Introduction

Anand Gadre

University of California, Merced, USA

Title: Advanced bioplymeric electrospun nanoscale fibers for controlled drug delivery

Time : 11:50-12:15

Biography:

Anand Gadre graduated with his BS in Applied Physics from the University of Mumbai, MS Degree at the Institute of Science, Mumbai and his doctorate (Ph.D.) from the Institute of Chemical Technology (ICT), Mumbai, (India). Anand joined University of Maryland (USA) as a Postdoctoral Research Associate and further continued working in Georgetown University at Washington DC. Anand was then appointed as an Assistant Professor of Nanobioscience at the College of Nanoscale Science and Engineering in the State University of New York at Albany and later was promoted as an Associate Professor of Nanobioscience with tenure. While working at CNSE, Anand also achieved his Master in Business Management (MBA) degree from the State University of New York at Albany. Since 2011, Anand has been working as Director of the Stem Cell Instrumentation Foundry (SCIF) at the University of California, Merced where he is currently administering core research facilities and pursuing his research in the areas of Nanobiotechnology.

Abstract:

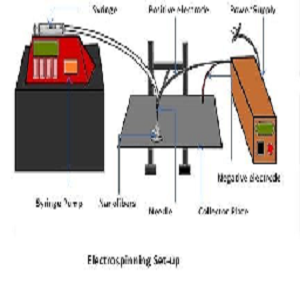

Advanced biocompatible polymers and co-polymers have been successfully implemented to generate electrospun nanofibers for variety of biological and biomedical applications. This work focused on generating a biopolymeric drug delivery system using (Poly-Lactic- co-Glycolic Acid (PLGA). Controlled drug elution targets a specific location to avoid overdosing and thereby reducing the side effects of the drug. In this study, we prepared a local anesthetic (Lidocaine) as well as an antibiotic (Chloramphenicol) loaded PLGA nanofibers using electrospinning technique and evaluated the drug release activity at a stable rate. Electrospinning is performed by applying a large positive voltage (several kV) to a metal syringe tip, which dispenses a polymer solution. The potential field draws a fiber from the end of the tip and deposits a randomly oriented and non- woven mat of polymeric fiber on a grounded metal collector plate. Depending on spinning parameters, fibers ranging from as small as 100 nm to as large as several micrometers can be achieved. We can alter the fiber diameter to control the rate of delivery. Fibers of lager diameter will have smaller surface area to volume ratios and should therefore release drug molecules compounds at a slower rate, but for a longer period of time. Conversely, smaller diameter fibers could release drug molecules at a faster rate, which could be beneficial for initial treatment.

Structural and optical properties of such drug loaded fibers confirmed the presence of drug molecules. Systematic drug elution experiments using UV- spectrophotometry were performed to observe possible indication in the absorbance change as the drug elutes from the nanofibers over the period of time. Drug loaded biopolymeric nanofibers also showed limited cytotoxicity on fibroblasts with viability greater than 96%. Such drug-loaded biopolymeric nanofibers can be applied via different routes, such as implantation, injection, and/or oral administration for a wide range of medical treatments.

Patrizia Cinelli

University of Pisa, Italy

Title: Sustainable Composites based on biopolymers and natural fibres

Time : 12:15-12:40

Biography:

Dr. Patrizia Cinelli PhD in Chemistry at Pisa University partly performed at the United States Department of Agriculture (USDA), Peoria, IL, USA. Over 20 years of experience in materials science, polymer processing and characterization, biodegradation and life cycle assessment. She is co-author of over 50 papers in peer-reviewed journal, 9 book chapters, and 8 patents on innovative materials. She is assistant professor of applied chemistry and Materials Technology at Master Degree student of Construction Engineering and Architecture at Pisa University. She has worked in over 15 EC project from FP5, FP6, FP7 and Horizon 2020, directly following technical management, proposal writing, scientific activity, and reporting

Abstract:

The utilization of “bio-polymers” for production of bio-based composites has attracted interest of various application sectors ranging from packaging to automotive components and other high value applications.

Advantages of natural fibres are their lightweight, relative cheapness, being bio-based, and the fact that they can compete well with conventional reinforcements such as glass and aramid fibres for terms of strength per weight of material. The strength of the bond between fibres and matrix is substantial for the best mechanical performances of a composite. Many factors interacting with each other affect the complex process of the fibre/matrix adhesion, which be influenced by the chemical nature of the polymeric matrix, manufacturing methods, processing parameters, surface modification of the fibres or by additives like adhesion modifier agents. For production of composites with bio based biodegradable polymers, it is important to address fibres pre-treatment and/or to use compatibilizing agents. These approaches are reviewed in the present contribute with reference on specific researches carried on in our laboratories.

Bernaerts Katrien

Maastricht University, Netherlands

Title: Increasing the solubility range of polyesters by tuning their microstructure with comonomers.

Time : 12:40-13:05

Biography:

Katrien Bernaerts, born in 1978 in Neerpelt (Belgium) graduated as a licentiate (master) in chemistry from Ghent University (Belgium) in 2000. From 2000 – 2005 she performed in PhD in polymer chemistry in the group of Prof. Du Prez at Ghent University (Belgium) on the synthesis and evaluation of stimuli (pH and temperature) responsive copolymer architectures by combination of different polymerization techniques. After PhD, Katrien spent 7 years in industry, doing research in the field of coatings and fibers. Since 2012, she started as assistant professor polymer chemistry at Maastricht University. Her main research interest is the synthesis of renewable, functional (co)polymers with a variety of architectures via different chemistries and the study of their structure-property relationships in several fields of application e.g. stimuli-responsive polymers, organic coatings, fibers, organic membranes, engineering plastics and biomedical applications.

Abstract:

ω-Pentadecalactone (PDL) is a biobased 16-membered macrolactone that can be derived from renewable resources. Its regular structure makes it highly crystalline and thus interesting as a biobased replacement for linear low density polyethylene. However, its solubility is very limited (chloroform) which hinders the use of PDL polymers in other applications requiring large solubility range. Copolymerization with a branched lactone is one way to reduce crystallinity because it is expected to disrupt the co-polyesters’ microstructure. Nevertheless, it has been shown that the microstructure of PDL-based co-polyesters varies depending on the comonomer structure. A block copolyester is obtained with branched lactones while a random structure is obtained with unsubstituted lactones of various size.

It was attempted to break the crystallinity of PDL-based copolyesters with a view of increasing their solubility range. Therefore, PDL was copolymerized with the branched and biobased δ-undecalactone (UDL), whose homopolymer is amorphous. In order to assess the microstructure (random or block-like), monomer distribution within the PDL-co-UDL polyesters was assessed by 13C NMR. It was observed that crystallinity of the copolyesters was decreased but not suppressed as measured by DSC, partially because they did not display a fully random monomer order. Hansen solubility parameter determination however showed that the solubility range of the copolyesters was improved compared to PDL homopolymers.

Egle Conforto

Université de La Rochelle, France

Title: An optimized methodology to analyze biopolymer capsules by environmental scanning electron microscopy

Biography:

Egle Conforto, an Italian and Brazilian materials and biomaterials scientist, is specialized in Scanning and Transmission Electron Microscopy, which is the red wire of her career. She obtained her BSc degree in Physics and her MSc in Materials Science at Sao Paulo University in Brazil, and worked for 8 years in R&D using electron microscopy. Her PhD degree in materials for nanoelectronics applications was obtained at Ecole Polytechnique Fédérale de Lausanne, Switzerland, where she worked for 10 more years as head of new projects in biomaterials analyzed by Electron Microscopy. Since 2004 she is the Head of the Electron Microscopy Laboratory at University La Rochelle, being the responsible for its management and for research projects in corrosion and in hydrogen precipitation in Ti and Zr. She is also responsible for the supervisor of master and PhD research works, as well as for undergraduate, graduate and continuing education in electron microscopy

Abstract:

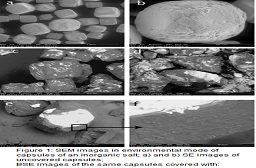

We propose an optimized methodology using Scanning Electron Microscopy (SEM) in environmental mode to study the surface characteristics and the internal structure of biopolymer capsules. Water vapor pressure in the 1.3 – 2.0 mbar range is introduced in the SEM specimen chamber during analyses to improve the electrical and thermal conductivity of the capsule surface, and to preserve it from damage. The main advantage of this methodology is that no preparation is required and, significantly, no metallic coverage is deposited on the surface of the specimen, thus preserving its original morphology. In particular, it avoids introducing preparation artefacts which could modify the capsule surface and shape, and mask information concerning important feature like porosities, roughness, coating continuity and cracks. Furthermore, chemical contrast is preserved in Backscattered Electron (BSE) images of unprepared samples, allowing visualizing the internal organization of the capsule, the quality of the envelope etc… Figures 1a and b show the surface morphology of uncovered capsules constituted of an inorganic salt by secondary electrons (SE) images. In Figure 1c and d, BSE images of the same salt coated by 10% of type A gelatin allows evaluating the coating permeability and the coating-core interactions. This information is also obtained from Figs. 1e and f where capsules of the same salt were covered by hydrogenated vegetable oil. We can observe fine details of gelatin and mainly fatty coatings, which are difficult to be analyzed by standard SEM techniques. For some simple fatty molecules like stearic acids for instance, environmental Energy Dispersive Spectroscopy (EDS) analyses have been successfully performed to obtain the relative concentration C/O. Finally, this methodology provides a reliable evaluation of the parameters used in capsule elaboration for research and industrial applications, as well as that of capsule functionality which is essential for the technological progress in this domain.

Christine Jerome

University of Liège, Belgium

Title: Chitosan, a promising biomaterial for tissue engineering

Biography:

Christine Jérôme, full Professor at the University of Liege, has expertise in polymer chemistry and passion in developing biomaterials to improve health and well-being. She developed green strategies for the synthesis, functionalization and processing of polymer materials, degradable or not, to precisely tailor their properties and design supramolecular structures customised to the targeted biomedical application and needs.

Abstract:

Statement of the problem: Polymer hydrogels resemble the natural living tissue due to their high water content and soft consistency. They find many applications in the design and production of contact and intraocular lenses, biosensors membranes, matrices for repairing and regenerating a wide diversity of tissues and organs. Derived from chitin, chitosan [1] is a unique biopolymer that exhibits outstanding properties, beside biocompatibility and biodegradability. Most of these peculiar properties arise from the presence of primary amines along the chitosan backbone. As a consequence, chitosan based hydrogels have shown a great potential for biomedical and pharmaceutical applications. Being degraded in a physiological environment into non-toxic products, chitosan is an outstanding candidate for short- to medium-term applications, such as tissue engineering. In this respect, the preparation of chitosan nanometric fibers mats is highly interesting as such structure mimics the one of skin extracellular matrix. Chitosan nanofibers can be prepared by electrospinning but suffer from weak mechanical resistance if they are used as such. Therefore, strategies allowing to generate chitosan based nanofiber mats exhibiting a mechanical resistance strong enough to be easily handled while keeping the peculiar features of chitosan hydrogels favoring the interaction with cells and soft tissues to provide efficient tissue reconstruction are needed. Findings: (i) combination of electrospinning with the layer-by-layer deposition [2-4] of chitosan, (ii) chemical cross-linking [5-6] of chitosan electropsun nanofibers and (iii) combination of chitosan/poly-caprolactone electrospun multilayers are three strategies that revealed to be efficient to improve the mechanical properties of chitosan nanofiber mats while preserving their biological properties. Conclusion and significance: the control of the nanofiber structure offered by the electrospinning technology makes the developed processes very promising to precisely design biomaterials for tissue engineering as demonstrated by preliminary cell culture tests corroborating the potential use of such systems in wound healing applications.

Maia Merlani

Tbilisi State Medical University, Georgia

Title: New biopolymer from Comfrey: Chemistry and biological activity

Biography:

Maia Merlani has completed her PhD from Tbilisi State University. She is a Senior Research Scientist at Tbilisi State Medical University, department of plant biopolymers.. Her field of interest is a chemistry and synthesis of natural compounds. She is the author of more than 55 papers in reputed journals and presentations at 60 international scientific conferences. She was granted Georgian Presidential scholarship for young scientists (1997), NATO scholarship (2002, 2003-2006) and Matsumae International foundation scholarship (2013). She is a member of organizing committee of several international conferences in the field of organic and pharmaceutical Chemistry.

Abstract:

Comfrey root has been used as a traditional medicinal plant for the treatment of painful muscle and joint complaints for centuries. Recently biologically active polymer has been isolated from Caucasian species of comfrey Symphytum asperum Lepech. and S.caucasicum Bieb. This polymer - poly[3-(3,4-dihydroxyphenyl)glyceric acid] (p-DGA) is a representative of a new class of natural polyethers with a residue of 3-(3,4-dihydroxyphenyl)-glyceric acid (DGA) as the repeating unit. P-DGA exhibits high antioxidant, antiimfllamatory, wound healing and anticancer activities. In order to compare biological properties of natural polymer with its synthetic analogues, racemic and pure enantiomeric forms of DGA as well as a methylated analogue of p-DGA - poly(MCDMPO) as a precursor of p-DGA were synthesized. The racemic monomer and its virtually pure enantiomers were synthesized via Sharpless asymmetric dihydroxylation of trans-caffeic acid derivatives using an potassium osmiate catalyst, a stoichiometric oxidant N-methylmorpholine-N-oxide and enantiocomplementary catalysts cinchona alkaloid derivatives (DHQ)2-PHAL and (DHQD)2-PHA as chiral auxiliaries. Poly(MCDMPO) was obtained via ring opening polymerization of 2-methoxycarbonyl-3-(3,4-dimethoxyphenyl)-oxirane (MCDMPO) using a cationic initiator.

Comparative investigation of antioxidant properties of natural polymer and its monomer revealed that the latter appeared 40 fold active than polymer, however anticancer efficacy of p-DGA against human prostate cancer (PCA) cells is more compared to its synthetic monomer. Poly(MCDMPO) did not show any activity against PCA.

Isabel Orlando

University of Westminster, UK

Title: Drug-free hydrogel based antibacterial hybrid polymers for wound healing applications

Biography:

Abstract:

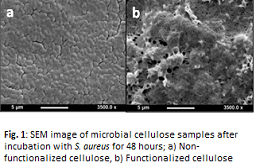

The unique mechanical and structural features of microbial cellulose (MC) make this polymer a promising starting material for applications in wound dressing and skin regeneration.1,2 MC presents a higher degree of crystallinity compared to plant cellulose, which results in better mechanical properties such as higher tensile strength and Young’s modulus. Moreover, the hydrogel-like structure enables MC to incorporate up to more than 90% its weight of water, ensuring an optimal level of moisture where applied.3 However, limitations to its use are related to the lack of antibacterial properties. Bacterial infections represent one of the major issues of concern for modern medicine because of the increasing resistance of bacteria against the traditional treatments.4,5 In this context, the need of novel strategies has become critical. HyMedPoly is a European project involving academic, industrial and clinical partners with an intent to generate a novel class of drug-free antibacterial materials based on natural and synthetic polymers as well as inorganic substrates. The focus of the research carried out at University of Westminster is to develop bacterial polymers with antibacterial properties for biomedical applications. In particular, this study aims to produce and chemically modify bacterial cellulose to obtain intrinsically active materials for wound dressing applications. A simple one-step reaction was performed to achieve the functionalization of the cellulose. The modified material was characterized using solid-state techniques such as Energy-dispersive X-ray Spectroscopy (EDX) and Fourier-Transformed Infra-Red (FT-IR). The activity of the antibacterial groups was evaluated by studying the inhibitory effect against Gram positive bacteria Staphylococcus aureus. Scanning electron microscopy (SEM) performed on modified MC samples after incubation with the bacteria showed a cell lysis based antibacterial activity (Fig. 1). Biocompatibility was assessed by testing the indirect cytotoxicity and the direct biocompatibility of the functionalised material using the HaCat cell line, a human keratinocyte cell line

Hao Bai

Karlsruhe Institute of Technology (KIT), Germany

Title: UV-curable printed phosphorus-polymer thin film

Biography:

Hao Bai is a fresh PhD student who has his expertise in optical spectroscopy and developing optical sensor systems for online quality control of printed polymers. He works currently at Light Technology Institute in Karlsruhe, Germany. His main research topics relate to optical characterization of polymer thin films, imaging and laser spectroscopy based monitoring system development for the UV curing process. The current research project is financed by German Federal Ministry of Education and Research.

Abstract:

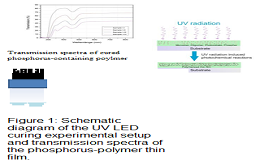

UV-radiation curing with photoinitiator and resins is used in variable industrial coating application. We develop a low-cost coating system through acylate polymer doped with luminescent pigment and UV curing process for white LED manufacturing. We printed the curable phosphor thin film doped with specialized acrylate coating formulation on fused silica glass substrate using spray coating and UV curing process. A homemade UV LED curing system with a wavelength of 365 nm is developed for coating process. This UV LED curing system has less energy consumption and environmentally friendly comparing with conventional gas-discharged lamp based curing system. Aluminium reflectors are integrated with the curing setup, which increased the total radiant energy flux. The glass substrate covered with unpolymerized resin layer is fixed on the top of the planer reflector during the curing process. Even low level of UV exposure (irradiance<0.5 W/cm²) is sufficient for complete polymerization. The surface profile of cured thin film shows ultra-high homogeneity and low root mean square value. The transmittance of the cured thin film adapts to the luminescence properties of white LED.

Oliver Meldrum

University of Queensland, Australia

Title: Hierarchical structure of mucin within the gastrointestinal tract and its interaction with dietary components

Biography:

Mr. Oliver Meldrum obtained a Bachelor of Science (Hons.) at the Australian National University and is currently undertaking a PhD at the University of Queensland. Oliver’s major research interest concern understanding the structure and rheology of mucus that lines the internal surfaces of the body and a focus on what food structure and food components are able to modify the physical and selective barrier properties of intestinal mucus.

Abstract:

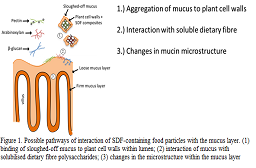

The adherent mucus layer is a vital component of the body’s epithelial surfaces. Mucus assembly is characterised by the presence of multiple levels of mucin structure at different length scales. This gives mucus its unique set of rheological and barrier properties that enable it to establish an effective physical and selective diffusion barrier as well as to hydrate the underlying epithelium. The rheological and structural characteristics of intestinal mucin, the functional component of the mucus layer and their interaction with cell wall components, that are liked with a number of health benefits are investigated. Biochemically well characterised porcine intestinal mucin has been utilised as a model for human mucins to characterise their viscoelasticity, structure and dynamics as a function of concentration, pH and Ca2+. The mesoscopic forces that mediate mucin were investigated using reducing, chaotropic and chelating agent agents. The rheological and structural characteristics of mucin were investigated using a combination of particle tracking microrheology, narrow gap oscillatory shear and high shear rheometry, and confocal microscopy. In this work, the complex rheological properties of the gelling mucus preparation are in a striking contrast with that of extensively purified mucin. The role and importance of non-mucin components have been elaborated, and the contribution to such interactions as hydrogen bonding, Ca2+-mediated links, and disulfide bonds has been evaluated. These bulk viscoelastic values are dominated by the elastic moduli, while the microrheological response is less dominant. We compare the ability of soluble dietary fibers and plant cell walls to alter the rheological and diffusion properties of purified intestinal mucin. Altering the organisation of mucus as a result of interactions with food components such as plant cell walls and soluble dietary fiber will provide new insights into the ways in which these nutritional components affect the barrier properties of mucus, and provide a possible underpinning mechanism contributing to their health promoting properties.

- Bioplastics

Session Introduction

Ivana Marova

Faculty of Chemistry, Brno University of Technology Czech Republic

Title: Application of PHA-based bioplastics in nanomaterials

Time : 16:25-16:50

Biography:

Ivana Marova work as Professor of Biochemistry at Faculty of Chemistry, Brno University of Technology in Brno (Czech Republic). Her scientific research is focused on microbial biotechnology, biochemistry, food chemistry and nanotechnology. After years of experience in research and teaching both in university and hospital institutions she with her collaborators has patented the biotechnological production PHA-based bioplastics on waste frying oil (PS3835CZ). This patent was licensed and, as HYDAL technology, circular and fully ecological biotechnology was awarded as the only Czech technology by “Frost and Sulliwan 2014 Technology Innovation Award”. At this time, the HYDAL technology is further developed by I. Marova team. Low-end applications (folia; food package) as well as high-end applications (fibers, particles and 3D printed materials for biomedicine, pharmacy and cosmetics) are developed.

Abstract:

Natural polyesters, in particular, polyhydroxyalkanoates (PHA), can be regarded as some of the most promising polymers obtained from renewable sources suitable as drug carriers. They degrade completely without releasing toxic side products. The purpose of this work was to investigate the possibility for the preparation of functionalized PHA-based nanoparticles and PHA-fibrous materials containing natural extracts with antimicrobial effect. Biotechnologically produced PHA on waste frying oil (900 kDa) was used. Liposomes/PHB particles were used for encapsulation of water and oil plant extracts. Size and stability was determined using DLS. PHB nanofibers were prepared via three different techniques: electro-spinning, force-spinning and wet spinning. Using wet spinning patented technology unique microfibers with sub-micron structure containing nanopores and micropores structure in the whole cross section being of diameter 200 nm – 1 mm were obtained (Fig. 1). Particles and fibers (individually and in combined form) were functionalized with selected natural extracts and examined via SEM, FLIM and FTIR-ATR methods. For antioxidant activity and releasing of active substances spectrophotometric determination was used. Antimicrobial properties of prepared particles, extracts and fibers were examined using the bacterial and fungal test systems. Cytotoxicity of selected samples was tested with MTT assay. The performed microbiological screening and MTT cell viability studies revealed that predominantly cinnamon- and clove-containing nanofibrous materials were effective in suppressing the growth of the G+ bacteria Serratia marcescens and the G- bacteria Escherichia coli as well as yeast strain Candida glabrata. All PHA materials displayed good short- and long-term stability. No cytotoxicity against human keratinocytes was observed up to 8% of oil extracts. The obtained materials are promising for antibacterial and antifungal wound dressing applications as well as for local treatment in cosmetics.

Paolo Benincasa

University of Perugia, Italy

Title: Developing thermoplastic films from wheat flours with different proportions of finely grinded bran

Biography:

Paolo Benincasa is Associate Professor at the Dept. of Agricultural, Food and Environmental Sciences of the University of Perugia, Italy. He has 25-year expertise in Crop Science and Technology. His research activity focused on the evaluation of agronomic aspects affecting crop yield and quality and on the management of crop residues and soil fertility in conventional and organic farming systems. Recent research developed together with his colleagues of the Materials Engineering group focused on biobased materials, looking at the factors (cultivar, environment, cultivation practices, post-harvest manipulation) that may affect the mechanical properties of derived manufactures. Novel findings are reported in articles published in high ranked journals.

Abstract:

The use of wheat flour to obtain bioplastics has been proposed about one decade ago (1). Recent works from our group demonstrated that tensile properties of thermoplastic films depend on wheat grain hardness and baking properties of refined flours (2-3), expressed as Chopin’s alveograph parameters (P, L, P/L, W) (4). Moreover, we used wholegrain flours for producing bulk samples and found that the bran worked as a reinforcement, affecting tensile properties in function of the bran grinding level (5). This is of relevance being the bran a mill by-product to dispose of. This study was aimed at developing thermoplastic films from flours with different bran proportions.

One refined wheat flour blend (F0, having P=64, L=99, P/L=0.65, W=182) from an industrial mill was mixed with three increasing proportions of finely grinded bran (treatments F1, F2 and F3, respectively). Roughly, F1 represented a wholegrain flour, F3 a grinding tail and F2 a mix 1:1 wt of F1 and F3. We tested several recipes and procedures, with progressive adjustments from that reported in Puglia et al. (2), and measured film tensile properties (strength, s; elongation at break, e) (2) (Figure 1).

By extruding the selected recipe (well defined proportions of wheat flour, glycerol, sorbitol, magnesium stearate, PVA/water solution) with a specific temperature profile (130-135-140°C), all flours gave films with s>2.0 MPa, while only F1 gave an acceptable e value. To further modulate e of films from F1, we investigated the blending with low melting biopolymers (PCL, PBAT) and plasticizer agents (citric acid). Results indicate that a 20-30% of PCL, plus citric acid, may give, even in presence of bran, a suitable deformation for crop mulching applications. All films were compostable and non-phytotoxic.

Results open perspectives for using wholegrain flours to obtain rigid and semi-rigid films, or deformable films suitable for mulching.

Huda S. Al-Battashi

Sultan Qaboos University, Oman

Title: Waste papers as a sustainable resource for the production of polyhydroxybutyrate (PHB) using Ralstonia eutropha ATCC 17699

Biography:

Huda Al-Battashi is a PhD student at Biology department, Sultan Qaboos University, Oman. She is working in biomass utilization for production of value added products. She did her BSc and MSc in College of Science, Sultan Qaboos University and graduated with Biotechnology major. She also has expertise in biopolymer production and chromium bioremediation

Abstract:

Polyhydroxybutyrae (PHB) is a biodegradable and biocompatible bioplastic that can replace conventional petroleum-derived plastics. The cost of PHB production is the major obstacle that hinders the production process and limiting their availability in the market compared with their petrochemical counterparts. In this work, PHB production was successfully implemented using waste papers, a cheap sustainable and renewable feedstock, as a raw material. The presence of 83% of carbohydrate in alkaline pretreated waste paper makes it a prospective source for bioplastic production. Alkaline-pretreatment (0.5% H2O2, 121°C, 30 min) of waste paper results in 91.93% glucose yield after enzymatic hydrolysis (37 FPU/g of cellulase and 50 CBU/g of β – glucosidase). Ralstonia eutropha ATCC 17699 was tested for its capability to produce poly-3-hydroxybutyrate (PHB) using waste paper hydrolysates as its sole carbon source in the deficiency of nitrogen source (20:1 C/N). Cells utilized the hydrolysate and accumulated 57 ± 1.83 % PHB of dry cell weight and produced 4.439 g PHB/l. The product yield coefficient was 0.3699 while 0.06 g/l/h volumetric productivity was achieved within 72 h of fermentation. Thus, waste paper hydrolysate is recommended as an excellent, cheap carbon substrate for PHB production.

Aleksandra A. Wroblewska

Maastricht University, New Zealand

Title: Beets to Biopolymers - Characterization of partially bio-based polyamides with elevated glass transition temperatures from rigid galactaric acid derivatives

Time : 17:35-17:55

Biography:

A main area of interest is the synthesis and characterization of biobased polyamides. In the past Aleksandra was working on the synthesis and modification of functionalized polyolefins at Sabic. Currently, Aleksandra became a PhD candidate in the newly formed group supervised by prof. Stefaan De Wildeman and dr. Katrien Bernaerts. Under their leadership she is synthesizing engineering plastics from biobased monomers. In this project, Maastricht University is part of the larger consortium “Beets to Biopolymers” with representatives of Cosun (NL), Philips (NL), Astron (NL) and Groningen University (NL). Together they aim at broadening the usage of biobased polymers in specialty applications. The effort made by the group from Maastricht University resulted in a couple of manuscripts which soon will be submitted to scientific journals

Abstract:

The focus of this research is the synthesis of amorphous polyamides from bio-based, cyclic monomers. Bio-based monomers are obtained from sugar beet pulp, as a side product in food industry. They are widely available and are gaining interest of researchers and industry through the last couple of decades. Their major disadvantage, which limits their wide spread utility, is the presence of different functional groups, which cause that those molecules are very often prone to degradation at elevated temperatures. On the other hand, their unique, rigid, cyclic structure contributes to better thermal properties of the product leading to more specialized applications for those polymers. Nonetheless, their incorporation into polyamides structure is challenging, mostly because of the elevated temperatures during the synthesis.

A comparative study was prepared investigating the synthesis of polyamides using bio-based building blocks, namely 2,3;4,5-(di-O-methylene)galactarate (GalXH) and 2,3;4,5-(di-O-isopropylidene)galactarate (GalXMe). Two different approaches towards the synthesis of biobased polyamides were tested: polycondensation in melt and polycondensation in solution via phosphorylation technique. The GalX monomers were combined with aliphatic, cycloaliphatic and aromatic diamines, resulting in amorphous polyamides with glass transition temperatures ranging from 50 °C – 220 °C. The obtained polyamides are stable at elevated temperatures above 300 °C. The polymerization of the GalXMe derivative results in polymer with narrow dispersities whereas GalXH gives polyamides with broad dispersities.

Joseph K. Muiruri

National University of Singapore, Singapore

Title: Biodegradable and tough pla-cellulose based composites via stereo-complexation

Biography:

Joseph Kinyanjui Muiruri is currently a Ph.D student in Material Science and Engineering (MSE) at National University of Singapore (NUS) and Institute of Material Science and Engineering (IMRE). Joseph graduated with a Master’s degree from University of Nairobi, Kenya in 2011. He is a recipient of A*Star Singapore International Graduate Award (SINGA). He holds a Bachelor’s degree in Textile engineering from Moi University, Kenya. His research interests focuses on biopolymers and their nanocomposites for industrial applications

Abstract:

In recent years, sustainability and industrial ecology concerns have driven the search for alternatives to petrochemical based products to a whole new level [1]. As such biobased polymers have a competitive advantage, due to their eco-friendly properties. Among biobased polymers, poly (lactide) ( PLA) has been a frontrunner based on its good mechanical properties, coupled with its ‘green’ attributes. However, PLA is inherently brittle, slow in crystallization and low thermal stability. PLA, therefore, does not meet some market requirements for high end applications. Research has shown that these limitations are ‘improvable’ and PLA applications landscape widened by careful design of rigid-rubber matrix PLA modifiers [2-4]. In order to obtain a good matrix-filler interface adhesion, phase morphology at the interface can be tailored with the aid of stereocomplex crystallites [5].

In this work, Poly(L-lactide) cellulose nanocrystals-filled nanocomposites were fabricated by blending of cellulose nanocrystals-g-rubber-g-poly(D-lactide) (CNC-rD-PDLA) and commercial PLLA, in which CNC-g-rubber was synthesized by ring opening polymerization (ROP) of D-lactide and ε-caprolactone mixture to obtain CNC-P(CL-DLA), followed by further polymerization of D-lactide to obtain CNC-rD-PDLA. X-ray diffraction (XRD), nuclear magnetic resonance (NMR) and solubility tests confirmed successful grafting of the rubber segment and the PDLA segment onto CNC. Stereocomplexation between CNC-rD-PDLA nanofillers and PLLA matrix was confirmed by FT-IR, XRD and differential scanning calorimetry (DSC) characterization. The PLLA/CNC-rD-PDLA nanocomposites exhibited greatly improved tensile toughness. With 2.5% CNC-rD-PDLA loading, strain at break of PLLA/CNC-rD-PDLA was increased 20-fold, and the composite shows potential to replace poly (ethylene terephthalate). SEM and small angle x-ray scattering (SAXS) investigations revealed that fibrillation and crazing during deformation of PLLA/CNC-rD-PDLA nanocomposites were the major toughening mechanisms in this system. The highly biodegradable and tough cellulose nanocrystals-filled PLLA nanocomposites could tremendously widen the range of industrial applications of PLA

Yakubu Muntaka Musah

University of Professional Studies, Ghana

Title: How can Ghana attain petroleum based plastic to achieve a clean environment?

Biography:

Yakubu Musah Muntaka finished his school at St. Peters International School early 1999s and later finished junior high school at kings International School in 2004. He completed high school from Adventist High School. He then moved further to the University of Professional Studies, Accra where he pursued his degree in Business Administration and held various leadership position as the local NUGS President. A year after he worked at National Health Insurance Scheme (NHIS) as an Assistant Administrator and moved to Milito Enterprise Dworwulu as an administrator in May 2015. Two years after he established his own enterprise, YM Ventures which deals with import and export of general goods. Currently he is pursuing Masters Programme in Oil and Gas at the University of Professional Studies, Accra.Company.

Abstract:

Bio plastics are plastics in which all carbon is derived from renewable feedstock. The application of biomass such as starch, cellulose, wood and sugar used to substitute fossil resources for the production of plastics which is widely accepted strategy towards sustainable development. In this way, a significant reduction of carbon dioxide emission. It also helps in the reduction of global warming. Ghana is a country located in the west of Africa, relatively richer in oil and gas resources, and produces about 50,000 tons of plastic waste daily from industries, factories, and households. As a result, the house of parliament has conferred an institution to collect plastic waste for recycling and disposal, but the company do not have the technical capacity and machinery to convert the tonnes of plastic waste into bio plastics. Due to this development, Ghana was recently ranked as one of the dirtiest country in Africa because the mandated company fail to collect the tonnes of plastic waste due to lack of capacity. As an agricultural country, that has been the second largest producer of cocoa in the world, most of the produce are agriculture in nature and for that matter can easily be degraded within shortest possible time. From Ghana statistical service, the country loses about $1.25 million through indiscriminate disposal of plastic waste and this could prevent Ghana from meeting the sustainable development goals. In addition, Ghana uses about 5 million litres of petrol and diesel daily that has a significant effect on the environment and the health of the citizens. With the introduction of the bio plastics it would help Ghana to reduce the excessive emission of the carbon dioxide and reduce global warming as well. Since Ghana was ranked 5th in Africa that produces and uses polythene in Africa, and experts are of the view that Ghana would be able to easily convert its organic substances into bio plastics.