Day 2 :

Keynote Forum

Eric Leroy

CNRS, France

Keynote: Processing of natural polymers based materials using ionic liquids

Time : 09:00-9:30

Biography:

Eric Leroy joined CNRS in 2008. He studied materials engineering and science at the National Institute of Applied Sciences (INSA) of Lyon. After obtaining a PhD in polymers and composite materials in 2000, he worked as a contracted researcher at the Donostia International Physics Center in San Sebastian, Spain, before joining the Alès School of Mines, France, as an assistant professor from 2002 to 2007. Author of 43 articles with over 1000 citations, he received the CNRS Bronze medal in 2013.Abstract:

The recent concerns for carbon management (including fossil fuels use and CO2 emissions) have drawn attention on biobased plastics, including natural polymers. When compared to petroleum based plastics, these polymers obtained from plants are generally considered as relatively weak, with low mechanical performances and more complex processability, due to water sensitivity and/or low thermal stability. Nevertheless, this current objective of replacing petroleum based commodity plastics may hide other opportunities for the use of natural polymers as structural and/or functional materials in applications that would take advantage of their specific properties. This approach will be illustrated by different examples of our recent research involving the use of ionic liquids as processing aids and functional additives for the design of functional and bioinspired materials from starch, cellulose and natural rubber.

Keynote Forum

Maximilian Lackner

Lackner Ventures & Consulting GmbH, Austria

Keynote: Sustainable PHB production from CO2 and sunlight using cyanobacteria

Time : 10:30-11:00

Biography:

Dr. Maximilian Lackner earned his PhD in 2003 and his habilitation in 2009 from Vienna University of Technology. He has held several senior leadership positions in the polymer industry in Austria and China. Dr. Lackner has founded 5 companies, amongst them one for antimicrobial polymers and one in the area of bioplastics, Lackner Ventures & Consulting GmbH. This company collaborates with JinHui Zhaolong, one of the largest PBAT manufacturers. The research interests of Dr. Lackner include PHA and PBAT. Lackner Ventures & Consulting GmbH runs a research project to produce PHB from CO2 and sunlight using cyanobacteria. Dr. Lackner has authored more than 100 scientific articles. He teaches materials science at the University of Applied Sciences FH Technikum Wien.Abstract:

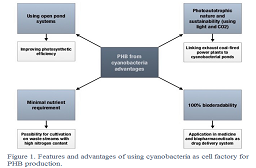

The use of conventional plastics has become a huge environmental concern. is a growing concern, leading to resource depletion and littering (e.g. microplastics pollution of the sea). Polyhydroxybutyrate (PHB) is formed as energy storage compound by several microorganisms. It has thermoplastic properties and can be a replacement for PP. PHB is fully degradable, also in the marine environment. Today, PHB is synthesized by heterotrophic bacteria using sugar fermentation. The relatively high costs of raw materials and continuous oxygen supply for the processing make PHAs expensive in comparison to other petroleum-derived plastics. Methodology and theory: The alternative is to use certain oxygenic cyanobacteria as cell factory. Cyanobacteria can store PHB under nutrient (P, N) limitation from renewable and sustainable resources sunlight and CO2 and due to their minimal nutrient requirement are the most promising host system for PHB production. However the growth rate and the PHB yield stay low. There exists no general method to increase PHB yield in cyanobacteria. This work aims at making cyanobacteria competitive by optimization of growth conditions and by strain selection. Findings: We screen for wild type strains which can naturally accumulate PHB. During our systematic screening we have discovered a cyanobacterium sp. strain which naturally accumulates a high PHB content under N and P limitations in comparison to other existing strains. The improvement of the strain is possible using process engineering and natural mutations. Significance: Our project can develop an economically superior bioprocess to enhance biomass growth and PHB productivity and prove feasibility to use CO2 for production of biodegradable plastics.

- Biopolymes as Materials | Green Composites in Biopolymers

Session Introduction

Takashi Yamashita

Tokyo University of Technology, Japan

Title: Development of Glycol-Lignin Derivatives for High Performance Hybrid Materials

Time : 11:20-11:45

Biography:

Professor Dr. Takashi Yamashita had been graduated from The University of Tokyo in 1984, then he had gotten Ph., D. from the University of Tokyo. He had worked for the University of Tokyo, Tokyo University of Science, and then he moved to Tokyo University of Technology in 2014 as the Department Head. His research interests cover development of photo-functional materials such as molecular machines, development of functional polyimides, development of the materials with nano-structure, fundamental theory on solid state photochemistry, and development of bio-mass materials. He had received Award of Photopolymer Science and Technology, and so on

Abstract:

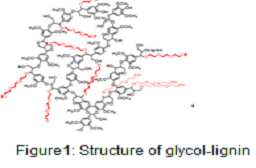

Lignin is one of the natural resources contained in coniferous trees up to 30% in weight, but it has not been utilized as a useful material up to now in contrast to the wide application of celluloses. Recently Dr. Yamada has invented “glycollignin”, which is soluble materials directly derived from coniferous tree chips by the solvolysis with oligo-ethylene glycol. We have developed hybrid film materials with the glycol-lignin and clays which have excellent properties such as insulation, gas barrier, surge resistance and so on as well as thermal stability, and which are now applied as gasket packings FRP matrices and so on. In order to improve the film properties and processability of the glycol lignin, we prepared several derivatives of the glycol-lignin. Phenolic hydroxyl groups and the hydroxyl groups of ethylene glycol chains on the glycol-lignin were determined as 1.89mmol/g and 2.35mmol/g, respectively based on the acetylation method. Then several functional groups such as diisocyanates, dianhydrids, chlorides, epoxides and so on were introduced on the active hydroxyl moieties to the materials. Introduction of (di)anhydrides afford the material water-solubility which improved the fabrication process so much. Addition of diisocianates gave water-containing-elastic gelly materials. Thus chemical modification of the glycol-lignin has opened a door to the wide application of the materials from the view point of sustainable engineering.

Elisabete Frollini

University of Sao Paulo, Brazil

Title: Bio-based materials from renewable resources: A brief overview

Time : 11:45-12:10

Biography:

Elisabete Frollini is the Head of the Macromolecular Materials and Lignocellulosic Fiber Group, and is currently the coordinator of the Center for Research on Science and Technology of BioResources (Institute of Chemistry of Sao Carlos, University of Sao Paulo, Sao Carlos, Sao Paulo, Brazil). She has expertise in bio-based polymeric materials from biomass with an emphasis on lignocellulosic biomass, which has also been used within the scope of biorefinery.

Abstract:

Our research is focused on the use of raw materials which come from renewable sources and it aims at replacing those derived from petrochemical routes. In this context, cellulose derivatives have been synthesized for diversified applications1, polymers have been prepared for applications such as films, as well as matrices in composites reinforced with lignocellulosic fibers2,3, which have also been used as reinforcement of biopolymers obtained on an industrial scale4. In addition, bio-based mats have been prepared from the electrospinning of solutions obtained from the dissolution of lignocellulosic fibers and/or from their main constituents, combined or not with other polymers5,6,. The methodologies used in these studies have followed what is described in the respective papers. Ongoing studies are conducted by using similar methodologies to those described in the papers already published2-6. Lignins and derivatives (such as lignosulfonates) have successfully replaced phenols in the synthesis of phenolic resins subsequently used as matrices in composites reinforced with lignocellulosic fibers (such as sugarcane bagasse, coconut, sisal, curauá), as well as polyol replacements in the synthesis of polyurethanes (combine or not with castor oil), which were later used as matrices and also as films. Recent studies, as well as those in progress, have shown that the properties of mats such as the diameters of ultrafine (submicron) and nanometric (diameter ≤ 100 nm) fibers, tensile properties, among others, can be tuned by the electrospinning of solutions obtained by the simultaneous dissolution of lignocellulosic fibers or the constituents thereof (cellulose and/or lignin) and a polymer, both when the fibers are randomly oriented and when they are preferably oriented in a certain direction. The set of results obtained in the mentioned studies, as well as in others not cited herein, has generally met the expectations and also matches the worldwide tendency to seek raw material from renewable sources that leads to products with good properties.

12:10-12:40 Poster Presentations BP-01 to BP-10 @ Foyer

12:45-13:15 Poster Presentations BP-11 to BP-19 @ Foyer

Lunch Break 13:15-14:00 @ NCafé

Lovely Mathew

Viswajyothi College of Engineering and Technology, India

Title: Development of potentially biodegradable cellulose nanocrystal reinforced PBS-HBPP bionanocomposites

Time : 14:00-14:25

Biography:

Dr. Lovely Mathew has completed her Ph D from Cochin University of Science and Technology in 2006. She was the Professor of Chemistry Faculty in Newman College, Kerala since 1981. After her retirement in 2015, now she is working as a Professor and Project coordinator (Research) in Viswajyothi college of Engineering and Technology, Vazhakulam, Muvatupuzha, Kerala, India. She has published more than 20 papers in reputed international/national journals and has presented several research papers in various international conferences abroad. Her research area is natural fibre/nanocelluose reinforced polymer composites/Nanocomposites. She has completed several major research projects funded by DST, UGC KSCSTE, etc.. She is a registered guide of International and Inter University Centre for Nanoscience and Nanotechnology, Mahatma Gandhi University, Kottayam, Kerala ,India

Abstract:

A cost effective green approach has been used for the preparation of cellulose nanocrystals (CNC) from isora fibre which is a bast fibre obtained from the bark of Helicteres isora plant. The process involves microwave liquefaction followed by persulphate treatment. CNC’s were extensively characterized by SEM, TEM, AFM, TGA WAXRD etc; to establish the morphology, aspect ratio, crystallinity, thermal stability etc. The aim of this work is to study the property enhancement of Poly butyl succinate (PBS)- hyper branched polyester polyols (HBPP) blends by adding CNC’s at different proportions to give green composites with potential applications in areas such as food packaging and medicines. Biodegradable (PBS) / (HBPP) blended films were processed using a brabender twin-screw compounder machine. This paper reports a single step reactive extrusion process for the fabrication of thermally stable PBS-HBPP grafted CNC’s bio nanocomposite films using dicumyl peroxide as a cross linking agent. The effect of addition of CNC particles on the mechanical, thermal and barrier properties of PBS-HBPP blends were studied. Spherulitic morphology, chemical structure and crystalline structure of neat PBS and PBS-HBPP blended films were examined by optical polarizing microscopy (OPM), FTIR spectroscopy and WAXRD respectively.. The addition of HBPP increased the toughness, and wettability of the film. FTIR spectroscopy studies showed that the PBS-HBPP blend was grafted on CNC through a stable C- C bond formation. This strong chemical link led to the efficient transfer of modulus of CNC’s to the PBS-HBPP blend thereby increasing the tensile strength and young’s modulus to a greater extent. Significant reduction in water vapour and oxygen permeability rates was also observed for PBS-HBPP nanocomposite over neat PBS. Experimentally, it was observed that the CNC’s wt. content, size and morphology are the parameters that substantially influence the mechanical, thermal and barrier properties of the composite samples. The surface of the nano particles act as initiators for network formation, as observed by a scanning electron microscope (SEM) image of the fractured sample

Biography:

Fabio Silvestri obtained his PhD in Material Science from University of Milano-Bicocca working on organic electronics (Prof. G. A. Pagani). During the doctoral studies, he also worked at Northwestern University (Prof. T.J. Marks) and Universidad Autonoma de Madrid (Prof Torres) on synthesis and characterization of new materials, and as a post-doctoral fellow at ETH Zürich, in the Prof. F. Diederich group. He then moved to Dow Chemical, working on polyurethane foams, and later on he joined Trocellen as Product Development Manager. He is now Innovation Manager for Trocellen group: his focus is to find new technology driven opportunities.

Abstract:

Chemically cross-linked polyethylene (XLPE) foams can be considered as a commodity material, due to the high volumes and the relatively low price compared to other polymers and foams. Furukawa Electric, the shareholder of Trocellen Group, filed the first patent on this topic in 1968, almost 50 years ago, so we are not talking about an innovative technology. However, polyethylene is still an interesting material with a lot of different application, ranging from insulation to footwear, from automotive to sport and tapes.

Our new vision is “Making a difference – shaping the future”, so we have started to think about a solution to provide a safe and comfortable future with products that make a difference.

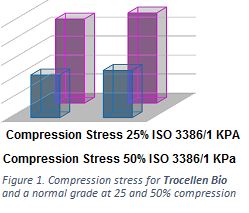

For this reason, we have decided to develop Trocellen Bio, a new foam that anticipates a precise request from the market, giving to our customer the opportunity to decide between the normal grade and a more sustainable one. This is because with this approach we can strongly reduce the CO2 emission, something it was never done in this field, at least at industrial scale. The most important thing is we can do it without any compromise in terms of physical-mechanical properties. As you can see in Figure 1, the compression stress at 25 and 50% is the same for the foam produced with Bio-based and petrochemical based polyethylene.

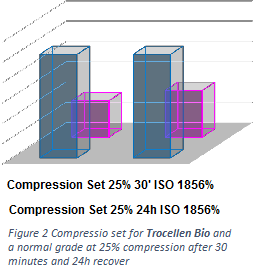

The same if we consider another mechanical property, the compression set (Figure 2).

As you can see, the values are very close to each other, underlying that this is a real alternative to the actual foam on the market, and a sustainable approach is possible.

Shuhua Zhang

Shanghai University of Engineering Science, China

Title: Processing Optimization and Characterization for PLA/MgAlCu-LDH/PVP Composite Microsphere

Biography:

Shuhua Zhang has completed his PhD from Harbin University of Science and Technology, and visiting studies from Lawrence Berkeley National Laboratory as a senior research scholar from September of 2013~ September of 2014. She is the associate professor of materials in polymer materials and engineering of Shanghai University of Engineering Science now. She has published more than 30 papers, an academic monographs and owned 4 authorized invention patents of China

Abstract:

In order to improve the mechanical properties of polylactic acid(PLA), PLA/MgAlCu-LDH/polyvinyl pyrrolidone(PVP) composite microsphere was successfully prepared on the basis of seminal emulson polymerization with PLA and PVP as monomer, MgAlCu-LDH as intercalating agent. Design-Expert 8.5 software was employed to optimize the processing technology with two steps. Firstly, single factor was analyzed based on the mass fraction ratio of MgAlCu-LDH to PLA, PVP concentration and stirring speed range being 1/15~1/8, 1~2%, 800~1200r/min, respectively. Secondly, the interaction effects of three factors were discussed according to the analysis of the software. The results show that the influence factors to microspheres size were as follows: the stirring speed > the mass fraction ratio of MgAlCu-LDH to PLA > PVP concentration. The optimized processing technology of microspheres indicates that the mass fraction ratio of MgAlCu-LDH to PLA is 1/15, the concentration of PVP is 2%, the stirring rate is 1200r/min. The structure and morphology of the dried frozen composite microsphere were characterized by XRD, FT-IR and SEM. The intercalation of part of the PLA into the gap of MgAlCu-LDH would be responsible for the new peaks on XRD spectra of MgAlCu-LDH and the disappear peaks at 1750cm-1, 1200cm-1 assigned to C=O on FT-IR spectra of PLA, which proves PLA/ MgAlCu-LDH/PVP composite microsphere was successfully prepared. Interestingly, some tinny channels resulted from volatile solvent on the surface of microsphere may be benefit for biocompatible

Marco Frediani

University of Florence, Italy

Title: Pyridine and Bipyridine End-functionalized Polylactide: Synthesis and Catalytic Applications

Biography:

Abstract:

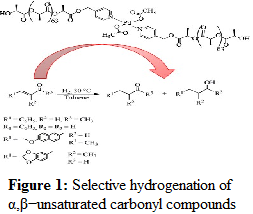

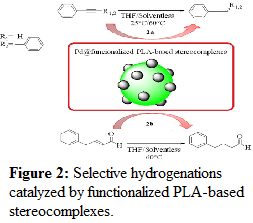

The search for new recyclable hydrogenation catalysts stimulated the synthesis of a great deal of heterogeneous metal-supported catalysts(1). In this context, mainly metallo-supramolecular polymers and block copolymers found a wide range of applications as catalyst support due to the unique possibility to tune the chemical and physical properties of the polymer backbone combined with its low cost, good performance and recyclability under real catalytic conditions(2, 3). In addition, the solubility of functionalized polymers in certain solvents, while they are insoluble in others was successfully employed to recycle the catalytic metal centers anchored to these polymers(4). Poly(lactic acid) (PLA) was functionalized with nitrogen containing aromatic groups such as pyridine and asymmetric 2,2’-bipyridine at the carboxylic acid-end of the polymer chain by means of tin octanoate-catalysed ring opening polymerization(5). The obtained macroligands have been successfully employed to coordinate Pd(II), which chemoselectively hydrogenated α,β- unsaturated carbonyl compounds to give the saturated counterpart as major product (Figure 1)(6) The catalyst was easily recycled upon a simple filtration process.

End-functionalized isotactic PLA chains with opposite stereochemistry were used to generate, through a known supramolecular self-assembling process, functionalized stereocomplexes, featured by a higher thermal and hydrolytic resistence compared to isotactic PLA(7). The chemical nature of the nitrogen ligand introduced at the chain end of PLA was exploited to stabilize Pd-nanoparticles (NPs) by interactions of the aromatic or nitrogen functionality with the NPs’ surface. The polymer- anchored Pd-NPs were generated by: (i) a classical approach which comprised the coordination of Pd(II) to the nitrogen donor atoms of the functional group prior to reduction with hydrogen; (ii) the interaction of solvent-stabilized Pd-clusters, obtained by the metal vapor synthesis(8), with the functionalized PLA-stereocomplexes. The polymer-supported Pd-NPs were successfully applied to catalyze the selective hydrogenation of selected alkynes to the corresponding alkene (Figure 2a)(9) and cinnamyl alcohol to the corresponding saturated aldehyde (Figure 2b)(10). A key finding with functionalized PLA-stabilized Pd-NPs was that the end-group controls the Pd-NPs’ size and distribution, exerting hence a pronounced effect on the observed chemoselectivity of the catalytic reactions.

Networking & Refreshment Break 15:40-16:00 @ Foyer

Biography:

Dr. Amit Jaiswal is presently an assistant professor at the Indian Institute of Technology Mandi, India. He has completed his PhD in nanotechnology from IIT Guwahati and post-doc from Washington University in St. Louis, USA and Technion – Israel Institute of Technology. His research interest is in the synthesis of nanomaterials for sensing, catalysis, drug delivery and diagnostic applications. Dr. Jaiswal has published more than 10 papers in reputed journals

Abstract:

Cationic polymers for gene delivery to cells both in-vitro and in-vivo have been studied in detail. However, studies have shown that cationic polymer such as polyethyleneimine (PEI) suffer from high cellular toxicity and poor biocompatibility. Graphene and its derivatives such as Graphene Oxide (GO) and reduced Graphene Oxide (rGO) have emerged as excellent nanomaterials for biomedical applications such as drug delivery, gene delivery, cellular imaging, biosensing, photothermal therapy, photodynamic therapy, tissue engineering etc due to their excellent physicochemical, optical and biocompatible properties. Here, we report the synthesis of a novel non-viral nano-vector for efficient gene delivery by functionalizing rGO sheets with a water-soluble biocompatible cationic polymer Poly (allylamine hydrochloride). GO sheets synthesised by improved Hummer’s method were simultaneously reduced and functionalized by PAH to form physiologically stable rGO/PAH nanocomposites. The optical, morphological, chemical, and structural properties of these nanocomposites were characterized in detail using UV-Visible spectroscopy, Raman spectroscopy, TEM, SEM, AFM, FT-IR and XRD respectively. Gel retardation assay using pEGFP clearly demonstrated the efficient DNA binding ability of these nanocomposites, thus validating the potential of rGO/PAH to be used as a non-viral gene delivery vector.

Biography:

Abstract:

According to the global trend in the world, many studies are conducted to valorize plant biomass as materials1,2. Plant fibers are used to reinforce composites and to enhance their properties. The lignin fraction produced by wood and paper industries, which is burnt now to produce energy3, should be valorized through chemistry for the synthesis of high value-added compound. In this work, ferulic acid and its derivatives, which can be obtained from lignin, were used to influence the aspect ratio of lignocellulosic fibers, one of the key parameters for mechanical thermoplastic's fiber reinforcement.

Two ferulic acid derivatives were synthesized by enzymatic chemistry following a green process4,5,6 and subsequently pulverized on hemp fibers. The first derivative was a macrobisphenol while the second one was obtained after the methylation of the phenolic functions of the latter. These pretreated lignocellulosic fibers were incorporated in a polycaprolactone matrix during a single screw extrusion process. Tensile test specimens were injected and mechanical properties were measured. Chemical analysis were conducted by SEC to measure the impact of the ferulic acid derivatives on the molar mass of the matrix. Rheological analysis provided information about the plasticizing effect of the ferulic acid derivatives on the materials. Hemp fibers, ferulic acid derivatives and crude polycaprolactone were also analyzed by Raman spectroscopy to define their spectral profile7.

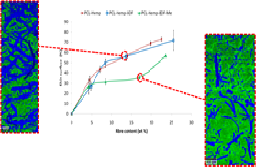

The microstructure of the composites was determined by Confocal Raman Imaging and was correlated with the mechanical properties measured by tensile tests. We evidenced that the very single methylation of the macrobisphenol led to significant differences on the mechanical properties and the structure of the composites. Two hypothesis were investigated to explain such effects: a stronger interaction between hemp fibers and ferulic acid derivative changing the microstructure and/or an increased plasticizing effect of the ferulic acid derivative on the polymeric matrix.