Day 3 :

Keynote Forum

Matjaz Kunaver

National institute of chemistry, Slovenia

Keynote: BIOMASS WASTE – A SOURCE OF RAW MATERIALS AND NANOCELLULOSE

Time : 10:00-10:30

Biography:

Matjaž Kunaver has done his MSc from the University of Leeds UK in 1991 and has received his PhD degree in 1998 at the University of Leeds, UK. He is a Senior Scientist Researcher at the National Institute of Chemistry, Laboratory for Polymer Chemistry and Technology, Ljubljana, Slovenia and is an Assistant Professor at the University of Ljubljana and Polymer Technology College. His main fields of research are the utilization of biomass as a feedstock for polymer synthesis and production of nanocellulose. He has published more than 50 original scientific papers and 6 patents.Abstract:

Cellulose containing Biomass represents an immense and renewable source for the production of bio-fuels and valuable chemicals. A little amount of this is used in industry and the remaining is leftover in huge quantities. Much effort has been devoted to converting these types of biomass into useful industrial and commercially viable products. In recent years, some effective processes have been found, such as thermochemical conversion producing several new products from these renewable resources. An overview of such applications and methods will be presented in this contribution. One of possibilities of converting biomass is the liquefactioni]. During liquefaction reaction, lignocellulosic components are depolymerised to low molecular mass compounds with high reactivity, high hydroxyl group content and can be used in many useful applications. A high energy ultrasound or microwaves can be used as an energy source to speed up the liquefaction process. The liquefied biomass was used as a feedstock in the synthesis of polyesters, polyurethane foams and adhesives. The same liquefaction process was used for the isolation of the nanocrystalline cellulose from biomass. The method is a novelty and a

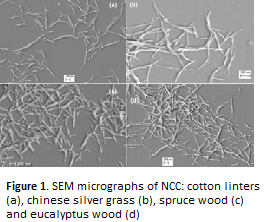

model procedure for NCC isolation from different natural cellulosic sources with high yields and with high crystallinity index[i].

The process of preparing NCC from different natural sources uses glycols as the main reactant and an acid catalyst in low concentration (only 3%). Here, during the one step reaction, lignin, hemicelluloses and the more disordered components of the cellulosic fibers are liquefied, only the crystalline cellulose remaining as a solid residue.

The liquefaction reaction, using glycols and mild acid catalysis, was optimized and applied to four model materials, namely cotton linters, spruce wood, eucalyptus wood and Chinese switch grass. The % recovery of the nanocrystalline cellulose, the crystallinity index of the nanocrystalline cellulose and the average crystal dimensions are presented in the Table 1. The main benefit of the process arises from the ability to prepare stable NCC suspensions in an organic medium at 10 times greater loadings than can be achieved in aqueous suspensions. The liquid residues contain significant quantities of levulinic acid and different sugars that were derived from cellulose and hemicelluloses.

- Biodegradable Polymers | Natural Polymers | Bippolymers Feed Stock Challenges & Opportunities | Biopolymers in Biofibers & Microbial Cellulose

Session Introduction

Marine Janvier

Chaire ABI – AgroParisTech, France

Title: Chemo-enzymatic synthesis and polymerizations of bio-based bisphenols derived from ferulic and sinapic acids

Biography:

Dr Marine Janvier is currently a post-doctoral researcher in Chemistry at the Chair ABI (Industrial Agro-Biotechnologies) in Reims (France). She has completed her PhD in green chemistry from University Claude Bernard (Lyon, France) where she studied the applications of isohexides as a new biobased platform for organocatalysis, developing an expertise in organic synthesis. She joined Professor Florent Allais' research group (Chair ABI) in 2016 for a post-doctoral fellowship dedicated to the use of syringaresinol as a platform molecule for the production of functional antiradical/antioxidant additives as well as monomer for polymerizations. Applications to epoxy-amine resins and non-isocyanate polyurethanes have shown the high interest of syringaresinol as a genuine renewable and safer replacement to toxic bisphenol-A. Those results have been published in peer-reviewed journals and presented in international congresses (ACS Philadelphia 2016 and ISGC La Rochelle 2017)

Abstract:

Novel renewable bisphenols were prepared through chemo-enzymatic processes under mild conditions from ferulic and sinapic acids.1,2 The enzyme-catalyzed steps have been optimized and lead to high purity grade bisphenols in high to excellent yields.

The antiradical3/antioxidant4 properties of these bio-based bisphenols were investigated and revealed activities similar or higher than that of current commercially available antiradical/antioxidant additives such as Irganox 1010®. The bisphenols were then used as monomers for the preparation of various types of polymers such as copolyesters,1 polyurethanes,1 polyolefins,1,5 non-isocyanates polyurethanes (NIPUs)6 and epoxy resins7,8,9. The newly obtained materials were then characterized by NMR, GPC, DSC, TGA and DMA. These analyses revealed not only good thermal stabilities but also a broad range of accessible Tg.

Biography:

Michel Dana defended its PhD in organic chemistry at the University of Bordeaux I in 1996. Michel works at SILAB since 1997 and is now manager of the new technology platform

Abstract:

Interpenetrating polymer networks (IPN) (1) have gained great attention in the last decades, mainly due to their biomedical applications. IPN present properties that can be very different according to the macromolecular constituents and that can be tailored by the process. Currently, IPN are composed of chemical polymers or cross-linked by using chemicals. Our study aimed to develop an IPN based on natural polymers and chemical free to obtain a biopolymer-based film with “second skin” (2) properties, biosourced, biodegradable and in accordance with the requirements of the cosmetic industry.

For this purpose, we studied the influence of different natural polysaccharides molecular mass and their ratio but also the natures and concentration of the cross linker on the IPN properties, in the manufacturing process. This approach led to the development of the eco-designed and patented IBPN technology® (Interpenetrating BioPolymer Network). The resulting material is composed of a galactomannans network from Caesalpinia spinosa (3, 4) and of a sulfated galactans network from Kappaphycus alvarezii (5, 6) ionically crosslinked. Thermodynamic analyses by DSC (Differential Scanning Calorimetry) and DMA (Dynamic Mechanical Analyses) associated with visualization by AFM (Atomic Force Microscopy) and SEM (Scanning Electronic Microscopy) revealed the physical-IPN organization of the obtained material. Applied to the skin, this natural physical-IPN forms a “second-skin” film since it protects against mechanical aggressions (-14%, P<0.05), pollutants (-47%, P<0.001) and irritants (-22%).

In conclusion, the resulting biopolymer-based film has outstanding “second skin” properties. It is biodegradable and perfectly suitable to the cosmetic industry requirements. The sourcing of the two plants used for its production is sustainable. This study demonstrates the interest of the interpenetrating biopolymer network technology for new promising applications

Martin Koller

University of Graz, Austria

Title: Production of Polyhydroxyalkanoate (pha) Biopolyesters based on food-industrial waste- and surplus materials

Biography:

Martin Koller is working in the Office of Research Management and Service, c/o Institute of Chemistry, University of Graz, NAWI Graz, Heinrichstrasse 28/III, 8010 Graz, Austria

Abstract:

Scope: Value-added conversion of waste streams form food industry towards microbial biopolyesters [poly(hydroxyalkanoates), (PHAs)], used as biodegradable “green plastics”, is presented by two case studies: The utilization of lipid-rich waste fraction from slaughtering and rendering industry and of carbohydrate-rich waste from dairy industry. Process viability is demonstrated based on experimental results and economic appraisals, and by introducing strategies for the recycling of waste streams of the PHA production process itself.

Background: Our increasing demand for safe and convenient packaging materials and other plastics motivated mankind to produce more than 300 Mt annually of highly recalcitrant plastics, which are predominately based on limited fossil resources. Resulting piles of plastic waste, greenhouse gas emissions, global warming, together with the ongoing depletion of the fossil resources, provoked a tremendously dynamic “green plastic” market. Critically analysing various available “green plastics” often reveals severe shortcomings regarding the attributes “biobased”, “biodegradable”, “compostable”, and “biocompatible” that “green plastics” have to fulfil according to valid regulations [1]. In this context, the life cycle of PHAs, accumulated as microbial intracellular carbon- and energy reserves, justifies classifying them as “green plastics”. They are based on renewable resources and undergo complete biodegradation during composting. Molecular composition and material performance of PHA are pre-defined in statu nascendi during biosynthesis. Chemically, PHAs encompass thermoplastic short chain length PHA (scl-PHA) and elastomeric medium chain length PHA (mcl-PHA). Possible fields of implementation encompass compostable packaging, medical and pharmaceutical formulations and items, biodegradable latexes, or nano-particles. Low-quality PHAs can be converted to chiral compounds, novel biofuels or other green energy carriers [2]. PHAs must compete with their petro-chemical opponents both in terms of material performance AND economically. Up to now, PHA production resorts to expensive feedstocks of nutritional value, thus contributing to the current “plate-vs.-plastic” controversy. Switching to carbon-rich waste-streams of diverse industrial processes upgrades industrial waste streams, preserves food resources, and enhances the economics of PHA production [2].

Our case studies: Availability of suitable carbon-rich feedstocks defines the location of an envisaged PHA production facility. Processes developed in our recently performed R&D projects (acronyms ANIMPOL and WHEYPOL), financed by the EC, resort to abundantly available waste streams of the European food industry:

- ANIMPOL project: Surplus lipids from slaughterhouses (annual quantities in Europe: 500,000 t) can be transesterificated to crude glycerol (CG) and fatty acid esters (FAEs, biodiesel). Saturated FAEs (SFAE) counteract the application of biodiesel as engine fuel, but can be converted to PHA. Integrating PHA production into existing biodiesel facilities, SFAE-based PHA can be produced at less than 2 €/kg. Both SFAE and CG constitute precious carbon sources for production of either thermoplastic scl-PHA or highly elastic, amorphous mcl-PHA. [3-5]

- WHEYPOL project: In Europe, more than 14 Mt of surplus whey accrue at dairies every year, which causes growing environmental concern. Especially in Northern Italian regions, numerous huge dairy companies are located, which dispose of around 1 million litres of whey daily, often by simply pouring it into the sea. We profited from the fact that lactose, whey´s main carbohydrate, acts as substrate in various bioprocesses like PHA production, and used it to produce thermoplastic scl-PHA. Here, cost estimations suggest an already competitive production price below 3 €/kg [6].

- In addition to the choice of the appropriate raw materials, it is pivotal to close the material cycles of the PHA production process itself and of the subsequent PHA-recovery process, especially when using extremely halophilic microbial production strains, which require environmentally hazardous cultivation media [7]. Recycling experiments revealed that highly saline spent fermentation broth and cell debris can successfully be returned to subsequent fermentation batches as microbial salt- and nutrient source; this approach lowers the overall PHA production costs, and reduces environmental risks, as was demonstrated by LCA studies. Such LCA studies clearly demonstrated the environmental superiority of our novel processes compared to the life cycle of petrol-based plastics [8-10].

Lela Amiranashvili

Tbilisi State Medical University, Georgia

Title: Identification of biologically active compounds from Symphytum (Boraginaceae)

Biography:

L. Amiranashvili has completed his PhD at the age of 27 from I. Javakhishvili Tbilisi State University. She is a research scientist at Tbilisi State Medical University I.Kutateteladze Institute of Pharmacochemistry, department of plant biopolymers. She has published more than 40 papers in reputed journals. Her field of professional interests is Bioorganic and Medicinal chemistry.

Abstract:

Recently high-molecular fractions were isolated from species of Boragenaceae family Symphytum asperum and S.caucasicum. Based on the IR and NMR spectroscopy data, poly[3-(3,4 dihydroxyphenyl)glyceric acid] (PDPGA) was confirmed to be the major component of these fractions. This compound represents a new class of natural polyethers with a residue of 3-(3,4 dihydroxyphenyl)glyceric acid as the repeating unit. Polymer possesses immunomodulatory (anticomplementary), antioxidant, antiinflammatory and wound-healing properties. Phytochemical investigation of roots and stems of Symphytum asperum L. was carried out in order to define starting substances for biosynthesis of PDPGA. The solid-liquid extraction technique was chosen as the first step for isolation the compounds probably containing the fragments of PDPGA, followed by the investigation using UHPLC-Q-TOF/MS technique. The UHPLC-Q- TOF/MS analysis of extracts of S. asperum roots/stems revealed the presence of low molecular weight compounds such as caffeic, rosmarinic, chlorogenic and salvianolic acids as well several oligomers. The obtained results show that the comfrey roots/stems can be used as a source for the isolation of low molecular weight biologically active compounds

Amandine flourat

Agro paris tech, France

Title: Synthesis and characterisation of new biodegradable polymers with antiradical and antimicrobial activities

Biography:

Amandine Flourat is researcher and head of chemistry department at Chaire ABI from 2012. The aim of Chaire ABI is the valorization of agricultural coproducts through microbiology, process engineering and green chemistry. Amandine Flourat develops new synthetic pathways using biocatalyst and biobased products to access high value molecules and new polymers.

Abstract:

Climate change and the depletion of fossil resources lead to a transformation of polymer industry. Now, demands are for sustainable polymers offering a wide range of applications. In this mood, we dedicated our self to the synthesis and the characterization of a new class of biobased aromatic polymers able to be degraded in aqueous media presenting a wide range of properties. To know about the potential field of application, we studied thermal stabilities, determined by ATG, which are higher than 270 °C, and glass transition temperatures. These ones are tunable depending of monomers’ flexibility and hydrogen bonding but always superior at 100°C. Then antiradical activities are determined by DPPH scavenging test. Whereas antimicrobial properties are tested on Gram + and Gram - bacteria.

Martin Masuelli

Instituto de FÃsica Aplicada-CONICET y FQByF-UNSL

Title: Rheology of alcayota gum

Time : 14.10-14:35

Biography:

Martin Alberto MASUELLI is Master of Surfaces Science and Porous Media (2003), and Doctor in Chemistry (2007), title obtained in National University of San Luis, Argentina. Member of the Institute of Applied Physics (INFAP) belonging to National Council for Scientific and Technical Research (CONICET), as Research Assistant, 2011. He won three scholarships. He is UNSL Adj. Professor. He is the director of Director of the Laboratory of Physical Chemistry Services, UNSL. He has published more than 19 papers in journals and has been serving as a reviewer and editorial board member of repute, 5 book chapters and 52 congress presentation. Guest Editor of the Books: "Fiber Reinforced Polymers-The Applied Technology for Concrete Repair," INTECH, Croatia, 2013; "Advances in Physicochemical Properties of Biopolymers”, Bentham Publishing, USA, April 2016; "Biopackaging", CRC Press, April 2017. Editor in Chief and founder of the Journal of Polymer Physics and Chemistry Biopolymers, July 2013. He is also a member of the Argentina Association of Physicochemical and Inorganic Chemistry (AAFQI), and Argentina Society of Environmental Science and Technology (SACyTA). Recognition of Excellence in the review of papers in 2012, Desalination, Elsevier. Director of Project PRO 2-2414, UNSL: "Regional polysaccharides: Purification and Physical Chemistry Characterization. Applications: Analytics, a Separative Processes and Food Industry”, 2014.

Abstract:

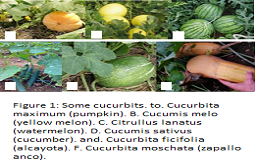

Cucurbita ficifolia is a creeping plant with a fleshy fruit, round and elongated, with a thick, smooth shell, resistant to low temperatures but not to severe frost (Figure 1). The mesocarp (pulp) is white with a granular and fibrous texture. The fruit was separated into three parts: peel, pulp and seeds. The pulp was dried and then ground to obtain the flour from which the hydrolysis was carried out.

Figure 1: Some cucurbits. to. Cucurbita maximum (pumpkin). B. Cucumis melo (yellow melon). C. Citrullus lanatus (watermelon). D. Cucumis sativus (cucumber). and. Cucurbita ficifolia (alcayota). F. Cucurbita moschata (zapallo anco).

Hot aqueous extracts were made to the moist pulp and a Cy (d) dispersed (used for rheology) solution Cy (d) solution (used for capillary viscosimetry) was obtained.

From Cy concentrations of 0.1%, 0.2%, 0.4% and 0.6% wt. in an aqueous solution of 0.1M NaCl, which acts as a stabilizer, the intrinsic viscosity was measured with an Ubbelodhe 1B viscometer and density with Anton Paar DM35N densimeter in the thermostatic bath at 25°C.

The hydrolysis procedure was performed on the Cy (d) dispersion, with 0.1M NaOH at 65°C for two hours and then precipitated with ethanol. The precipitate is washed with ethanol several times, obtaining a polysaccharide of average molecular weight having free oxydril groups called CyOH (d). To the above dispersion (CyOH (d)) was added 5 ml of glycerol and stirred cold for a few minutes to homogenize, these solutions were used to measure the flow ability curve. Also, dispersions of Cy (d) of different concentrations: 2, 3, 4, 5, and 6% in distilled water were prepared. Some of them were hydrolyzed, being named as CyOH (d) and measured with a Brookfield DVIII rheometer at a temperature of 25°C. The assay was repeated by adding 2, 4 and 5% glycerol to some of the hydrolyzed dispersions at temperatures of 35 and 40°C in a thermostatic bath.

The intrinsic viscosity was 149.83 cm3/g and the molecular weight was 1867000 g/mol (Marck-Houwink parameters of k = 0.00263 and a= 0.7583), with a hydrodynamic radius of 53nm, a shape factor of 3.12 and a hydration value of 47.63 g/g. Studies for CyOH (d) showed a thixotropic behavior for dispersed solutions which increased with increasing hydrolysis and glycerin and decreased with increasing temperature. The degree of thixotropy is higher for CyOH (d) compared to Cy (d).

Norma Mallegni

University of Pisa, Italy

Title: Green Composites based on PHA and natural fibres for applications in marine and land environments

Time : 14:35-14:55

Biography:

Norma Mallegni PhD student in University of Pisa, Department of Civil and Industrial Engineering, Master Degree in Chemistry, is working on copolymerization, blending and processing of biobased polymers for tuning properties and sustainability of biobased materials.

Abstract:

Green composites based on polyhydroxyalkanoates (PHA) with 10 to 20 wt% natural fibres were manufactured by extrusion and characterized. Two different types of fibres were used: fibrous wastes of the seagrass Posidonia Oceanica (PO) and sawdust (SD). PHA was successfully compounded with both fibres using 10 wt % acetyl tributyl citrate (ATBC) as plasticizer. Thermal, rheological, mechanical (tensile and Charpy’s impact tests) and morphological characterizations of the developed composites were conducted. The composites showed good thermal and mechanical properties, the impact energy-absorbing capability was markedly increased with increasing the fibre loading of PO or SD compared with that of the unfilled material.

The biodegradability of the composites based on PHA and PO fibres was assessed in sea water using standardized procedures based on the carbon dioxide evolution. Whereas, the biodegradability of the composites based on PHA and SD was assessed by measuring the amount of carbon mineralized during incubation under composting conditions. Both tests showed that the presence of the fibres facilitated the disintegration of the composite films increasing their biodegradation rate in the two different investigated environments.

Yuejiao Yang

University of Trento, Italy

Title: Keratin from camel and cashmere hairs: processing evaluation

Biography:

Yuejiao Yang is the third year PhD student of School of Environmental and Chemical Engineering, Shanghai University, China. In 2006, she received the scholarship from Erasmus program and now she is the visiting PhD student in Department of Industrial Engineering and Biotech Research Centre, University of Trento, Italy. She started to work with biopolymer during her mater degree and now she is focusing on extraction keratin from animal hairs by using Ionic Liquids.

Abstract:

Keratin, a fibrous protein, is abundantly available from a variety of sources including human hairs, wool and feathers. Keratin exhibits a stable three dimensional polypeptide structure consisting of a triple-helix of protein chains held together by a range of covalent (disulfide bonds) and noncovalent interactions. Like many nature biopolymers, keratin has shown promise for applications as biomaterial due to its intrinsic biocompatibility, biodegradability, mechanical durability, and natural abundance. However, the dissolution and processing of keratin in common solvents is difficult. Many reagents have the capability to reduce the disulfide bonds, preserve and maintain the protein structure; however these materials are often toxic.

In this work, we have investigated the dissolution and regeneration of keratin from camel hair and cashmere by using two ionic liquids (ILs), 1-butyl-3-methylimidazolium chloride ([BMIM]cl) and N,N-dimethylammonium formate([DMEA][HCOO]). Dissolution was conducted at 130°C for 10 hours and the water insoluble fraction was recovered by addition of water to the solution and then lyophilization. The remaining fraction, consisting of water soluble fragments, was dialyzed against water and then lyophilized to recover the fragments. The mechanism of dissolution by ILs was observed by microscope with single fibre. The structure and properties of the regenerated, water insoluble and soluble fractions were investigated by Amino acid analysis, SEM, FTIR, DSC and TGA with the comparison of raw materials, and the soluble fraction was characterized by protein quantification and gel electrophoresis.

Yunlong Jia

Hamburg University of Technology, Germany

Title: Multiple scale study of hydrothermal degradation in the interfacial regions of flax fiber/bio-based polyurethane composites

Time : 15:15-15:35

Biography:

Yunlong Jia is a doctoral candidate in Hamburg University of Technology with his research topic ‘durability of flax fiber reinforced bio-composites for structural applications’. He graduated with M.Sc. in mechanical engineering in 2012 and published four articles during his graduate program. After graduation, he was finically supported by the China Scholarship Council to conduct his research in the Institute of Polymer Composites.

Abstract:

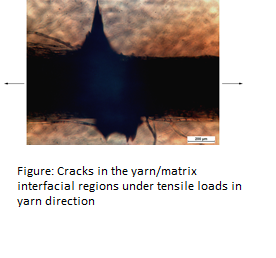

The recent years has witnessed a rising development of bio-composites in a wide range of applications. Much effort has been devoted to improve the performance of bio-composites. One of the most important aspect lies in the optimization of the interfacial properties. The intrinsic hydrophilic properties of natural fibers not only cause incompatibility with matrix but also make the interfacial regions very sensitive to weathering effects. The changing ambient temperature, humidity might cause degradation in the interfacial regions in the long term, which is among the least understood components of bio-composites. This study aim at a better understanding of hydrothermal degradation and its effects on the interfacial properties of flax fiber/bio-based polyurethane composites.

Experiments were elaborated at two scales. Single yarn fragmentation tests were performed as a reliable way to focus on the fiber/matrix interfaces. Corresponding unidirectional tensile tests were performed to investigate the influences of degradation at the scale of composites. It is found that interfacial bonding between flax fibers and matrix were weakened by the degradation caused by the hydrothermal effects. Results obtained at two scales correlate with each other well. Degradation in the interfacial regions can be well reflected by indicators from single yarn fragmentation tests like fragmentation development, fragmentation length distributions, and crack shapes etc. Interestingly, not only water absorption, but also water desorption cause degradation of fiber/matrix interfaces